In order to respond to increasing competitive pressure from countries with advantages in low labour cost (e.g. Asian countries), solutions for modern assembly systems have to be developed which meet high demands on flexibility, autonomy, and efficiency. In high-wage countries with significantly higher labour costs, competitive production costs can only be achieved based on an increased degree of automation. Furthermore, automation allows for implementing highly reliable processes and has the potential to increase product quality and improve working conditions.

However, a high degree of automation still correlates negatively with the flexibility of assembly systems. While from a hardware point-of-view promising progress has been made in developing modular and configurable assembly systems, there is a significant lack of corresponding software solutions to allow for an efficient exploitation of the available flexibility. This is the motivation for the DeLas consortium to develop and validate an integrated development environment (IDE) for automated precision assembly processes.

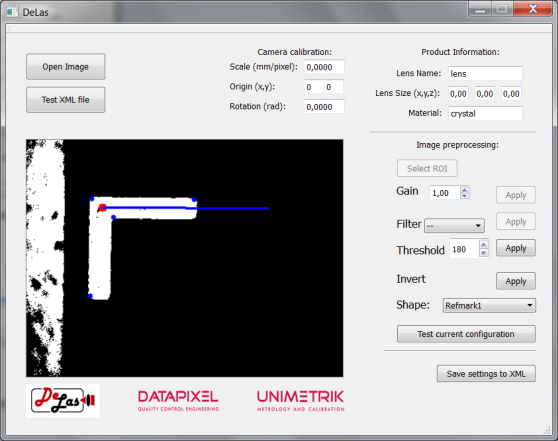

The objective is to bridge the gap between product development and automation control by means of methods and software tools for implementing complex sensor-guided handling and alignment processes. The DeLas approach proposes to integrate well-established engineering tools (for CAD modelling, product simulation, PLC and robot programming) as well as novel software modules (DeLas modules) through standardized communication interfaces and data formats. In DeLas, virtual and real commissioning of processes will be made available based on a virtual production environment. On the one hand, this environment organizes access to a virtualized model of the production system consisting of device and product models as well as models of optics and processes. On the other hand, the same environment allows for accessing the real system hardware directly, in order to close the gap from production planning to process programming and process execution.

The main goal of DeLas is the significant reduction of development and ramp-up times for the automated assembly of lasers and other optical systems. The resulting gain in efficiency will allow for the profitable automation of small volume production and thus enable especially small and medium-sized companies to strengthen the innovative nature of their product portfolio. Although DeLas focuses on lasers and optical systems, the concepts and results will be transferable to other domains of small and medium volume production and even mass production since the concepts in DeLas address technologically simple assembly tasks as well as complex sensor-guided tasks which occur e.g. in watch industry, automotive sensors, medical instrumentation, or 3D-MID

The main result of the proposed project will be a prototypical integrated development environment (IDE) for optics assembly processes. On the one hand the IDE connects to well-established engineering tools for laser development such as optics simulation and CAD. On the other hand, the IDE connects to hardware devices (sensors, manipulators etc.) and automation control systems providing human machine interfaces (HMIs). Based on a systematic process analysis the DeLas modules in the IDE will support the user in following process engineering steps:

- Targeted tolerance analysis (optics simulation) to define process requirements.

- Conception and design of component-specific assembly and alignment strategies.

- Development and implementation of complex assembly processes.

- Product-oriented description of handling processes based on geometric models.

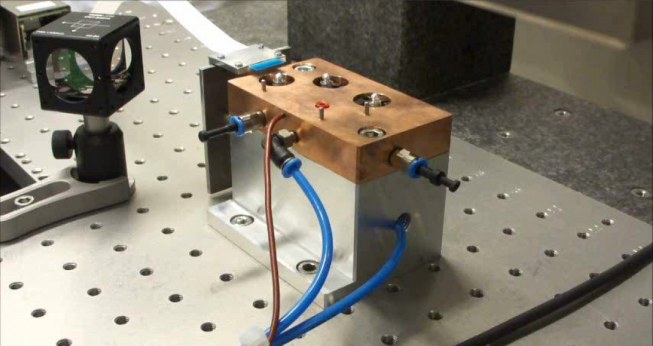

- Development of sensor-guided assembly processes based on virtual models, simulation, and direct hardware interaction.

- Development of function-oriented processes (e.g. active alignment) based on product models and optics simulation.

- Offline-programming and virtual commissioning of assembly processes.

- Direct execution or transfer of process descriptions to production systems.

The IDE closes the toolchain from product development to automated production and it bridges the gaps between product development, sensor-guided process development, and automation control for assembly in the field of optics. A key feature of the IDE will be the hardware-independent description of processes which allows for developing processes on dedicated development stations and transfer of the resulting processes to production systems. This reduces stand-still times induced by online programming and it allows for separating process development from production, e.g. for distributed process development between different departments or even different companies