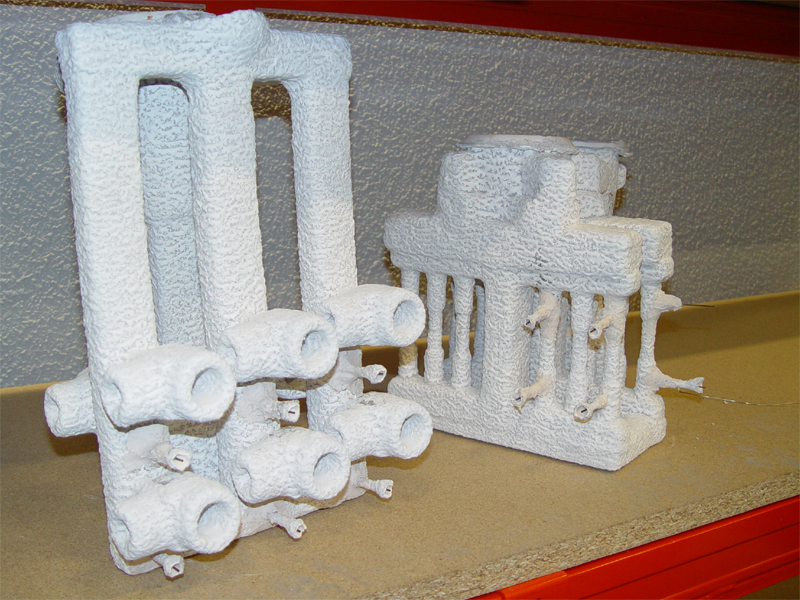

INVAUT is a MANUNET project developed in cooperation between companies from the Basque Country and North Rhein Westfalia regions. The main goal of the project is the development of the investment casting process for Magnesium alloys, applied to the manufacturing of specific automotive parts that are currently being manufactured in plastic and can be substituted by Magnesium castings.

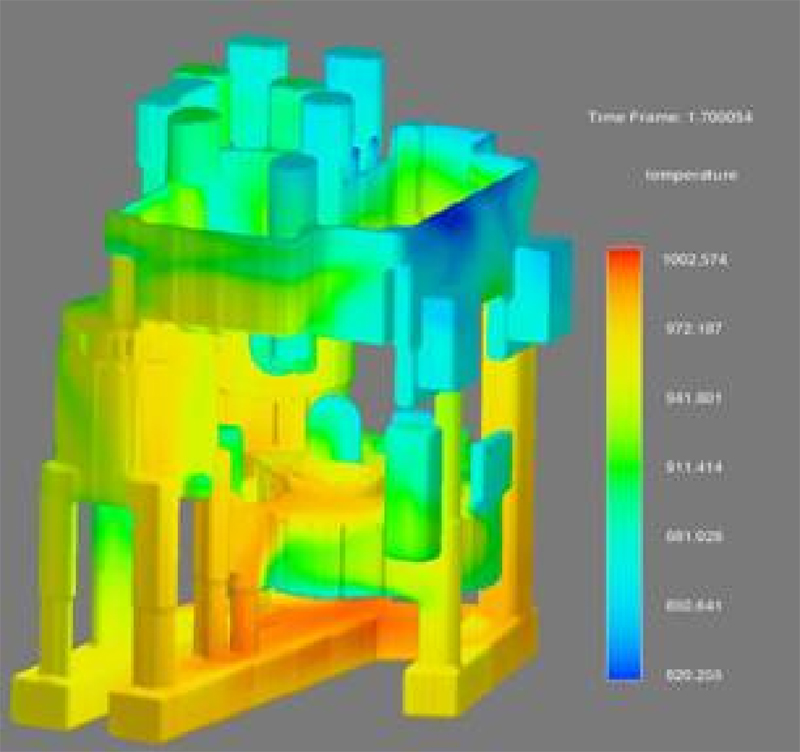

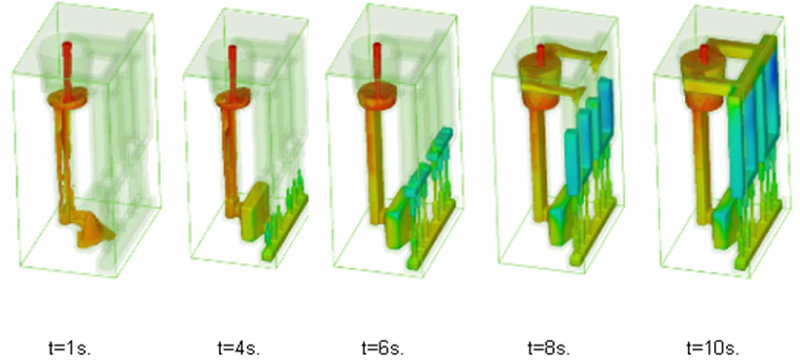

This development is carried out by means of the optimisation of investment casting process parameters for Magnesium alloys, the measurement of local solidification curves leading to the definition of microstructure, the verification of local mechanical properties (simulated vs. real), the definition and validation of a numerical model for the prediction of mechanical properties and the manufacturing of Magnesium investment cast prototypes for automotive applications to substitute current plastic parts.

The partners are fully complementary, since the consortium incorporates an investment casting foundry, a company specialized in the development of software for casting and solidification processes and an end-user manufacturing plastic housings for the automotive industry. A corporate research center and a university give the consortium the required support in fundamental process knowledge and material testing and characterization techniques.