The SOLE-CUT project rises from the necessity to develop innovative technical and monitoring solutions for the stone machining. Different solutions and applications have been analyzed both at cutting tool and inspection system level. In particular innovative SMA (Shape Memory Alloy), avant-garde sintering mixing and plasticization solutions have been investigated and analyzed; parallel mechatronic and sensorized solutions have been developed and later on implemented and tested in the last part of the project.

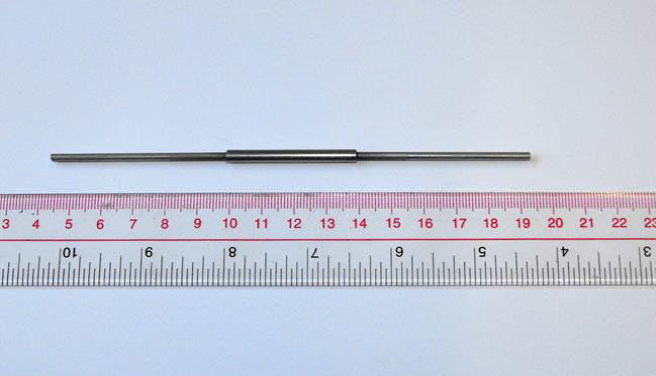

SOLE-CUT’s solutions, products, process and technologies may impact on maintenance activities, thanks to the independence provided to the customer and thanks to the real-time support in applying an approach that prevents malfunctioning through real time monitoring. Secondly, a selection of the best super elastic material (SMA) for the substitution of the standard steel cable has been performed considering mechanical performance, corrosion resistance, weldability and compatibility with other materials, availability on the market, reliability, manufacturing and processing costs, safety. Analysis of efficient technologies to develop a strong and secure joining of the diamond wire has been done thanks to the exploitation of laser technology (LIBS - BeamArGe) for the obtaining of a safe and durable solution.

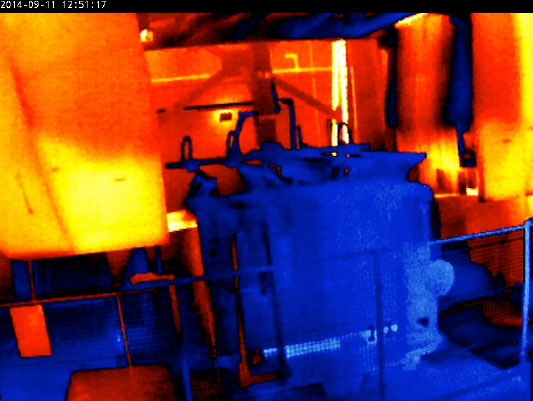

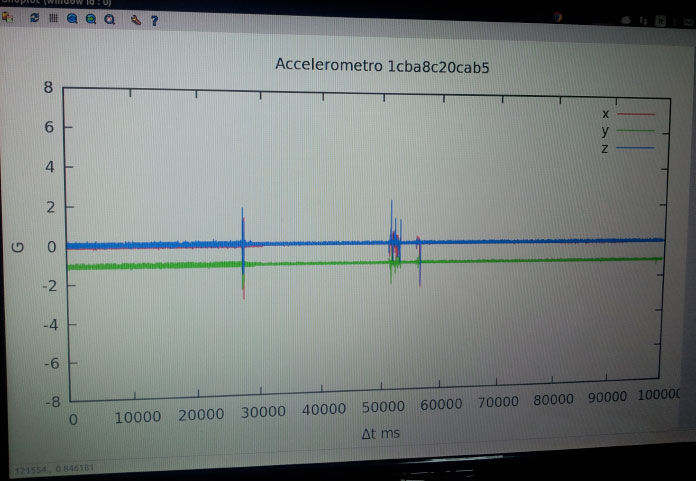

Indeed specific software have been developed to automatically monitor the cutting process by acquiring multiple signals such as video, thermal energy, three-axis acceleration, and audio. All these modules have been combined to realize a generic process monitoring system suitable for a variety of applications such as preventive maintenance.