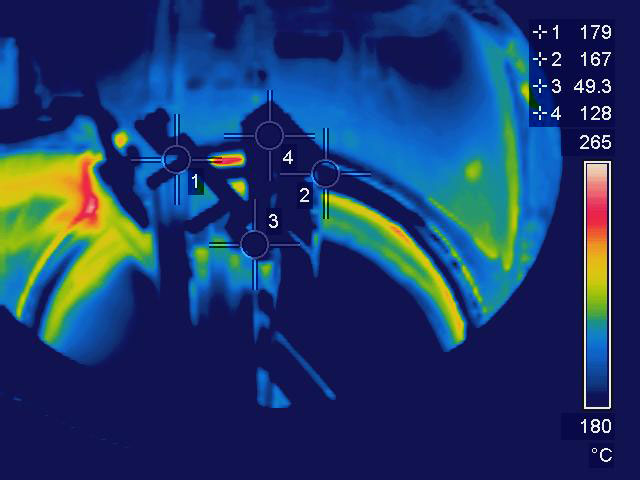

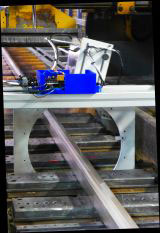

Current systems to control the dimensions of extruded aluminium profiles are deployed only after the profiles have had sufficient time to cool down and to reach their final dimensions. ESIPSE-AI endeavors to realise an innovative system to go beyond this state of the art and measure the profiles much earlier on in the process, at the exit of the press, when the profiles are extremely hot and in a dilated state. The early detection of out of specification material will result in much less scrap material actually being produced and successively reworked leading to a considerable energy savings for both phases.

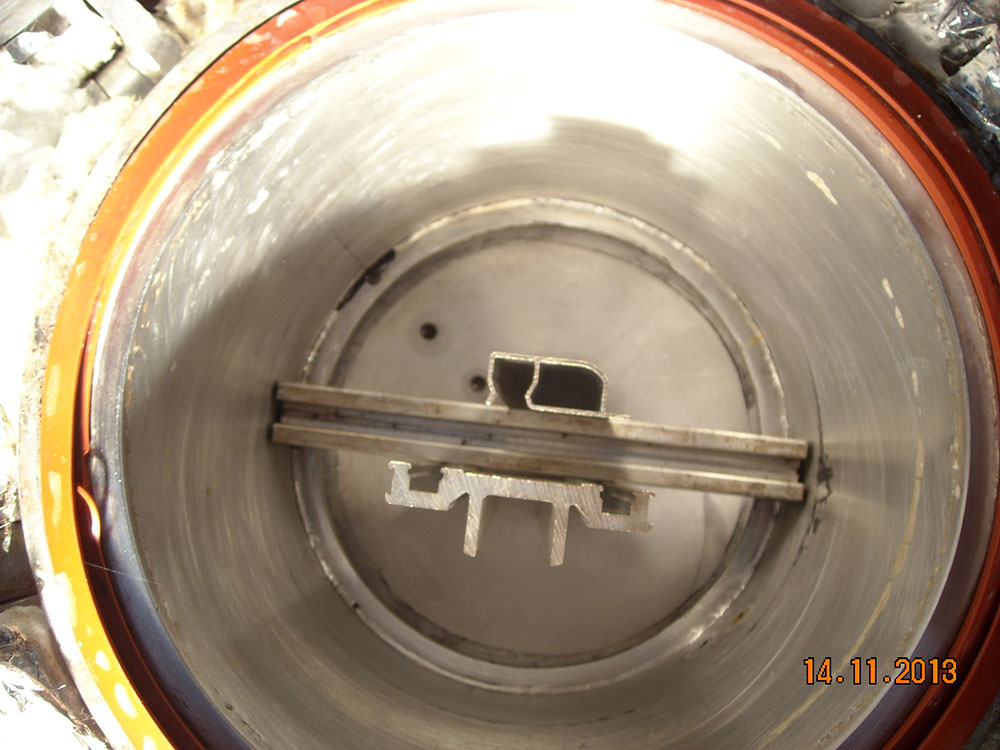

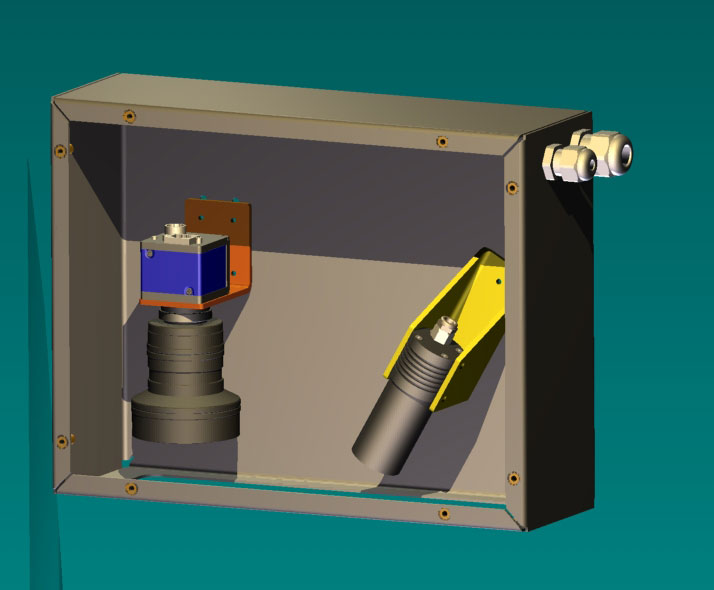

To achieve this goal several distinct challenges need to met. 1) how the profiles can be measured while hot and still on the press; 2) how to mount, move and configure the measurement system on the press; 3) how to predict the dimension that the profiles will take on after cooling down and contracting; 4) finally in the case of out of tolerance production what corrective actions should to taken.

The ESIPSE-AI consortium has been constructed in order maximize on its individual strengths in terms of process expertise, material and mechanical engineering, thermal / machine vision expertise and commercial presence within the aluminium industry.