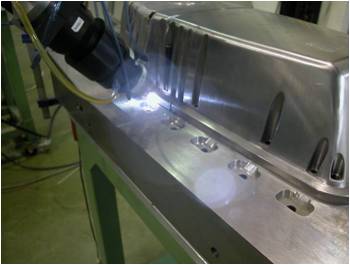

The project is focused in advancing in the field of laser material processing, and specifically, in the domain of integration of new flexible architectures for high productivity laser cladding in different applications/materials (moulds, dies, aeronautic engine components) and in different sizes, specially the large ones. The companies participating in the project seek to open their offer in the Laser market services. The technical goal is to apply the technology (laser surface cladding) in large components and in different positions (complex geometries) for these materials. Laser cladding is a manufacturing process which may allow to generate selective zones with outstanding properties of wear and corrosion resistance and also resistance to high temperatures oxidation. In maintenance and repair operations of worn or damaged components, this technology is relevant due to savings in costs and improvements in working service behaviour of the repaired zones.

FLEXLASCLAD - Flexible & High Productive Laser Cladding in Large & High Value Components

More images of the project

FLEXLASCLAD - Flexible & High Productive Laser Cladding in Large & High Value Components