The aim of this research project is to develop an innovative planarity contactless sensor, that can work in high temperature environment and then be positioned close to the furnace exit in industrial processes which contemplate baking or hot moulding stages for inspection purposes.

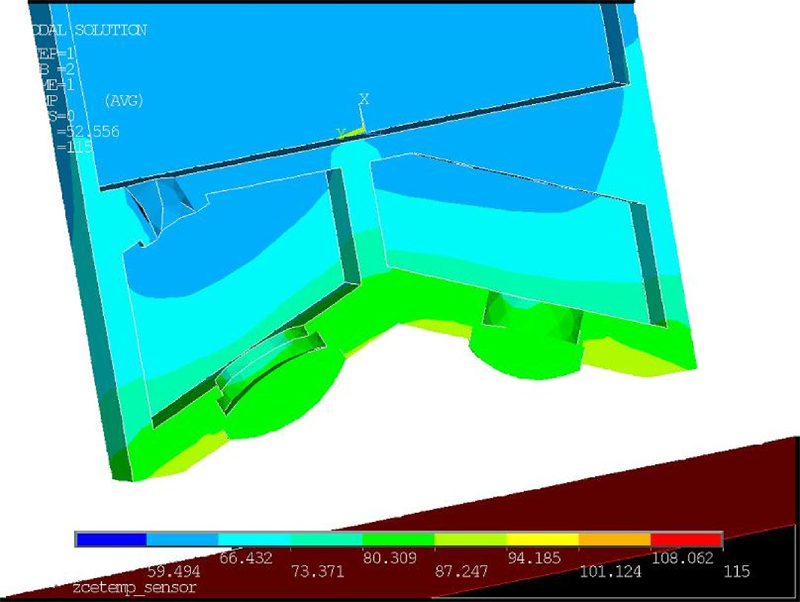

The new sensor named ZCE-TEMP will be developed in order to drastically reduce production wastes.

The ceramic tiles industrial sector has taken significant advantage of the strong evolution in the world of automation in recent years and all production phases have been addressed through various technical innovations, with the exception of the final stage of the manufacturing process. This is still performed without monitoring of the work conditions, and is concerned with inspection in order to sort tiles into distinct categories or to reject those found with unacceptable defects. The automation of the inspection stage and monitoring of the work conditions will then play a crucial role in advancing the development of the ceramic tile manufacturing process. The idea of NTS is to position the innovative planarity and temperature sensor near the furnace exit. This would lead to a quasi-real time reaction to process errors, drastically reducing production wastes and 2nd/3rd choice products.