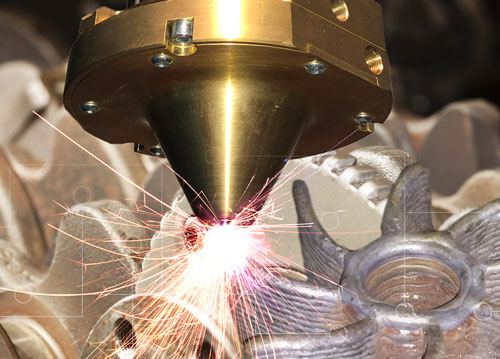

Additive Manufacturing (AM) could be counted among the disruptive technologies for large components as moulds or airplanes structures, made of materials classified as difficult to manufacture with conventionally applied industrial processes (as forging or machining). However, particularly for metal parts, AM technologies appear to be relatively slow for mass production, expensive and not up to the required standard. The goal of the project is the sustainable development and manufacturing of difficult-to-cut materials (such as steels and titanium alloys) by using AM technologies characterized by high deposition rates (i.e., Laser Metal Wire Deposition, LMWD, and Laser Arc Metal Wire Deposition, LAMWD) and followed by finishing machining operations with newly developed tools and tool holders. It is expected to obtain an AM head device prototype able to prepare medium/big components for dies and aerospace applications with reliable conditions (TRL7), ready to enter the market by 12 months after the end of the Project. Also, economic and environmental implications related with such an innovative hybrid/integrated approach will be assessed.