Metal spinning is a forming process that allows production of hollow, axially symmetric sheet metal components. One of the main problems of the metal spun parts production is the design of the process plan in order to achieve the appropriate properties of spun part surface and near-surface layers.

In the project Met-Spin the effect of process parameters influence on the spun part surfaces characteristics, such as radial and longitudinal strain distribution, residual stresses and corrosion resistance, have been examined. The parts of complex shape made of low carbon steel, stainless steel and aluminium have been taken in account.

Thanks to the project realisation the next results have been achieved:

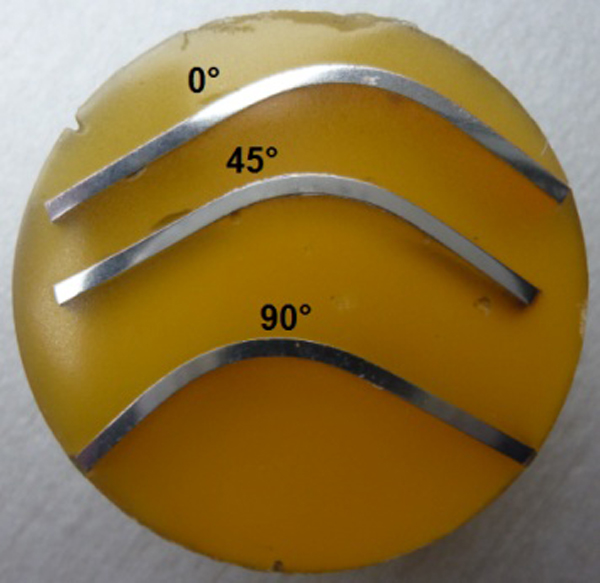

- the influence of the process parameters on the radial and longitudinal strain distribution has been determined;

- the corrosion resistance of spun parts in dependence on degree of plastic deformation has been verified;

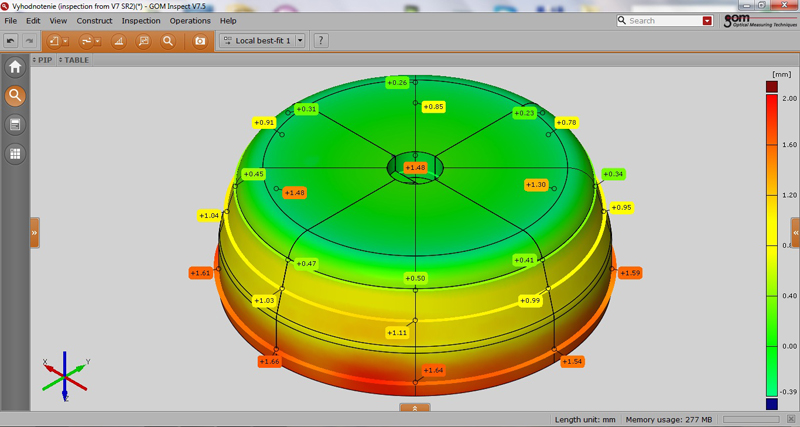

- the shape accuracy of spun parts depending on the spinning process parameters has been experimentally verified;

- the effect of process parameters on thickness distribution of spun parts was studied.

The results of experimental research, realised in cooperation of three partners will be used by Slovak companies Sandrik 1895, Co. Ltd. and Eiben, Co. Ltd. for innovation of spun parts production applied in automotive, gastronomy and medical industry.