The overall aim of the project is to find answers to the increasing needs in dies for the sector of cold and hot work forming. These demands are mainly the enhancement of the knowledge on the new generation of materials and treatments used in automotive part dies and in the increase of tool and die lives, as a first step in the reduction of part production costs.

The automotive sector is continuously introducing new materials in vehicles due to emerging strict requirements in terms of reduced weight and improved structural safety. New die materials must also be put into production to face up the formability of these steels. Herein powder metallurgical steels are starting to be used where aspects as repair were not covered.

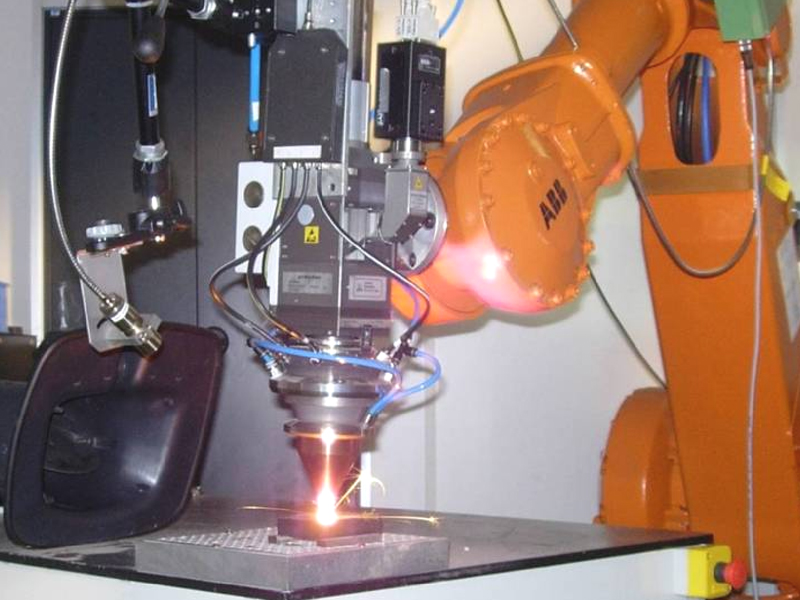

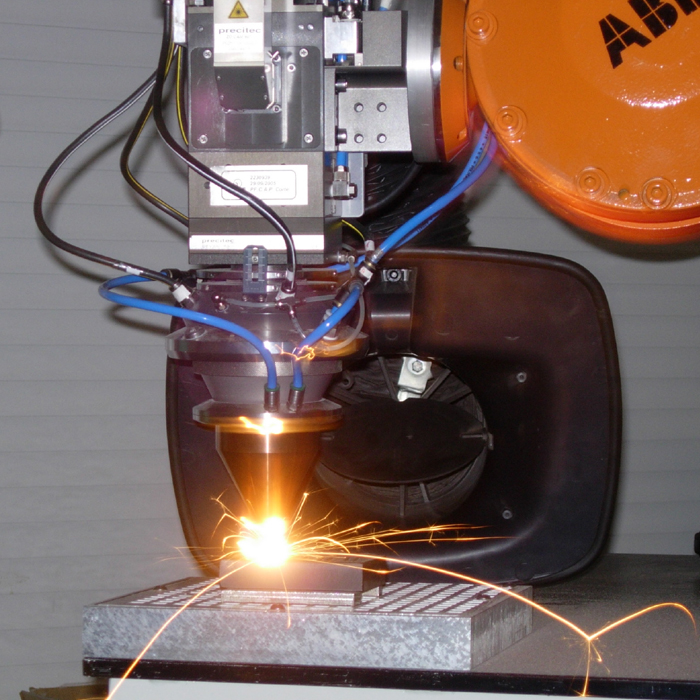

Therefore, the project innovation is in the development of laser cladding strategy into two main directions:

- cladding of nano-powders to generate local functional clad layers (local and graded) that match the local thermo-mechanical loads;

- cladding of innovative steels: as already stated, some of the innovative steels that are of interest for the die sector are powder metallurgical steels. These steels can hardly be repaired (or, in more general terms, a layer of the same base material can hardly be clad) with the traditional techniques, and consequently new cladding techniques have been developed. Thanks to the low thermal input, laser cladding seems to be the solution.

The final strategic goal has been to provide the SMEs with the knowledge, the guidelines and the optimal devices for the laser cladding of dies, aiming at the manufacturing of new high performance dies or at the reparation of worn dies.