Laser polishing is a new technique for an automated surface finishing of dies and molds with complex shaped geometries. As these geometries are currently often polished manually, laser polishing is of great industrial interest. Within ALPINE an adaptive laser polishing machine tool was developed and tested for the automated polishing of complex shaped 3D tools made out of GGG40 for glass making.

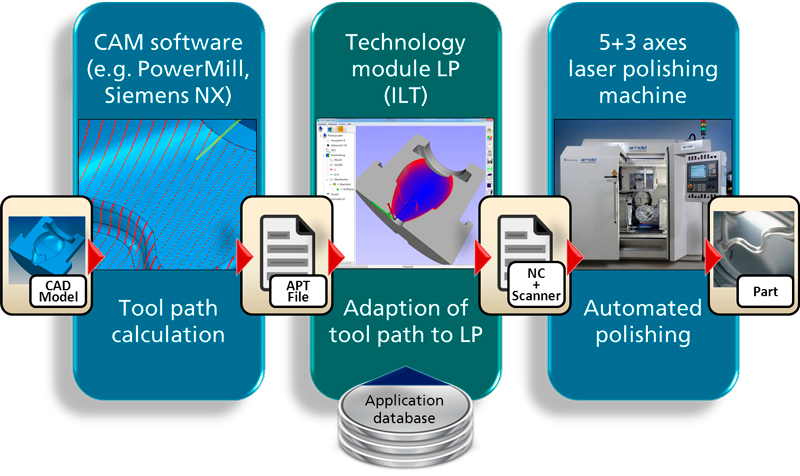

The machine tool consists of a 5 axes base machine for full 3D capabilities and a 3 axes laser scanner for the high dynamic movement of the laser beam required by the polishing process. For easy programming of the machine a CAM-NC data chain including a process parameter database was developed for a 5+3 axes processing. At the end of the project machine tool and CAM-NC data chain were tested under industrial conditions in the tool making workshop of Heinz Glas.

Furthermore within ALPINE fundamental process development was carried out and a numerical tool for determination of process parameters for the polishing process was developed. This tool helps to decrease the effort to find process parameters for laser polishing for new materials and applications.

The German partners in this research and development project were funded by the German Federal Ministry of Education and Research (BMBF) within the Framework Concept ”Research for Tomorrow’s Production“ and managed by the Project Management Agency Karlsruhe (PTKA). The author is responsible for the contents of this publication.